what strollo provided

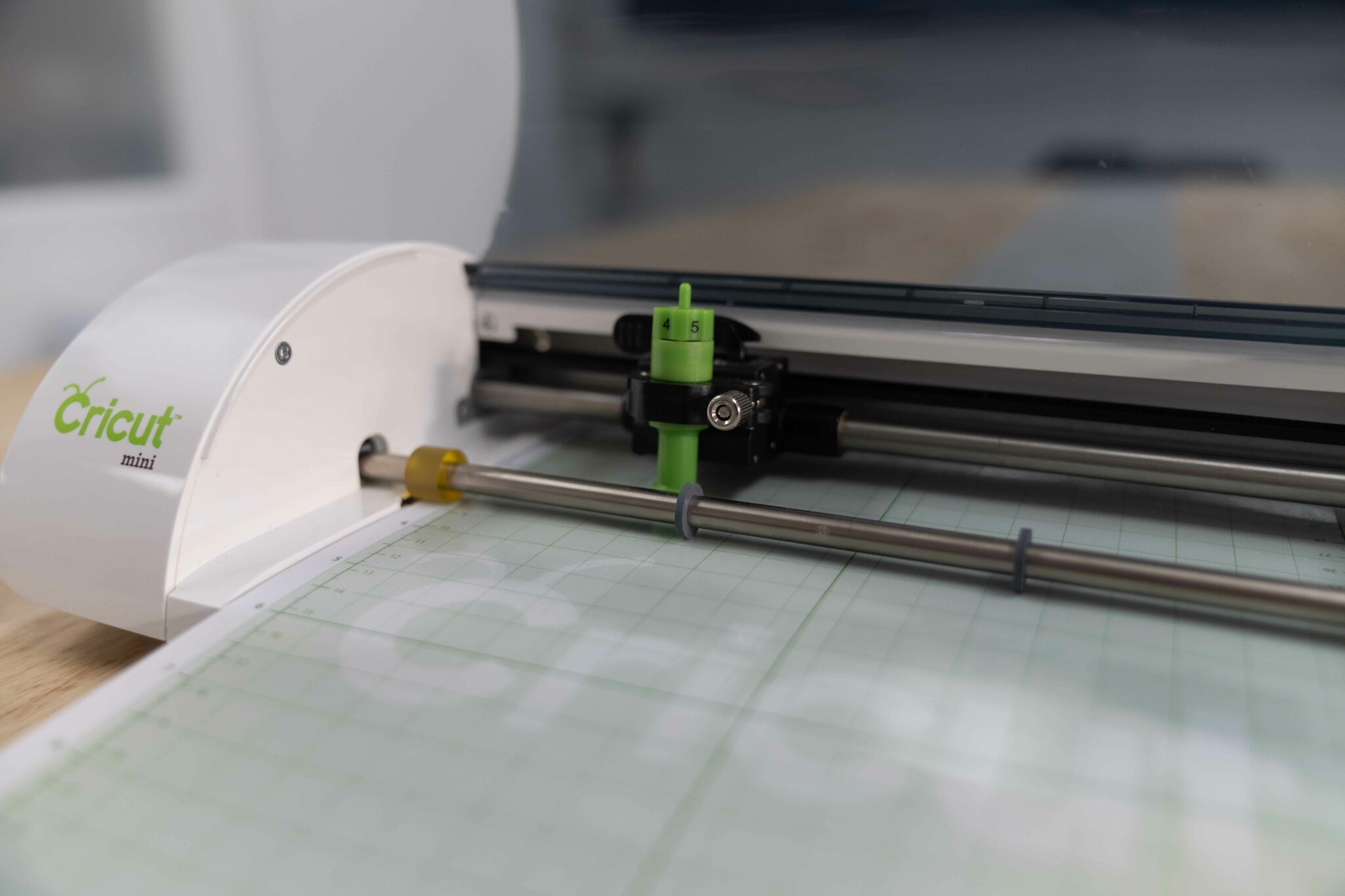

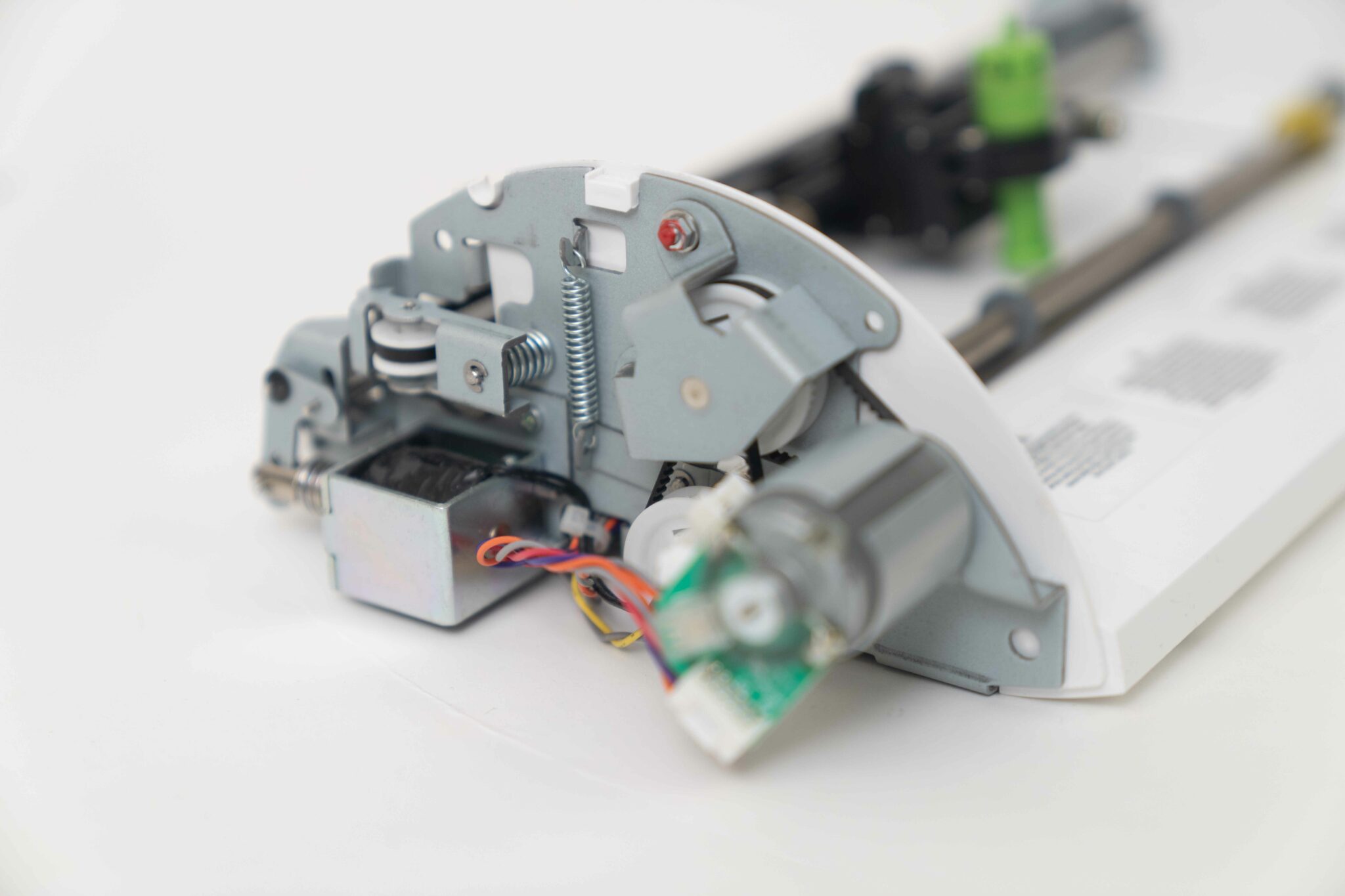

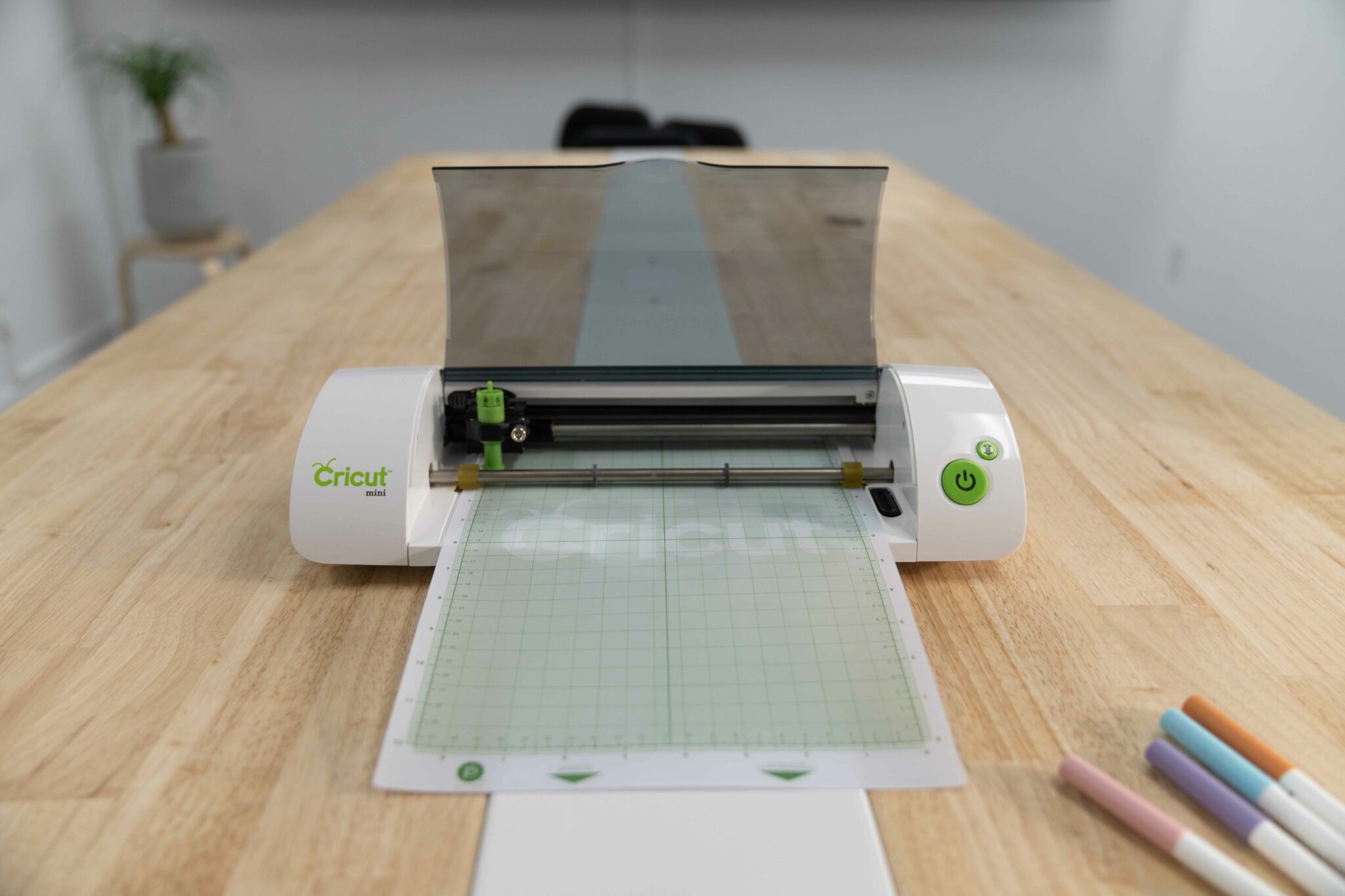

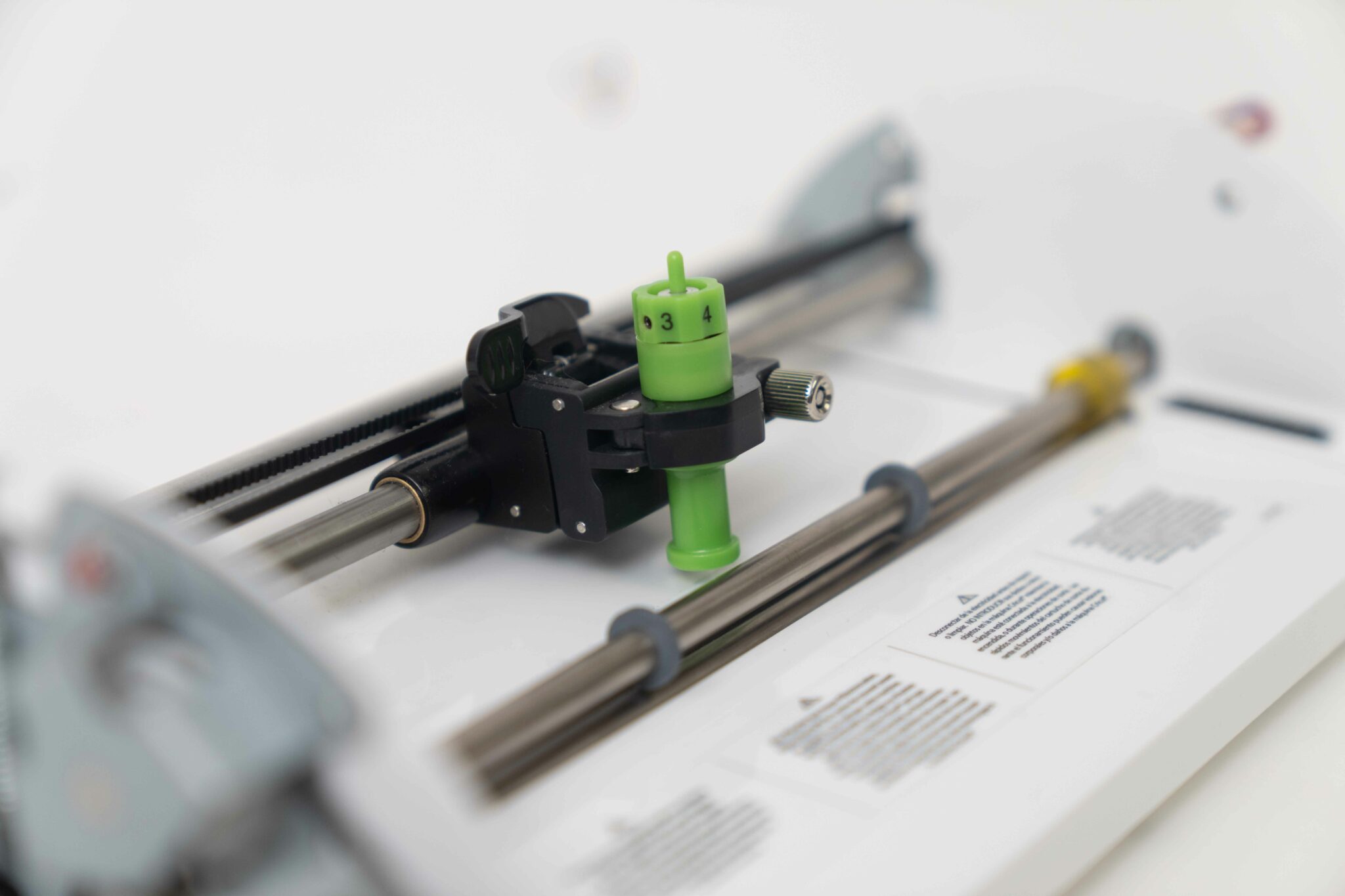

Strollo worked closely with a diverse team of engineers and developers across several organizations to bring this uniquely simple product to life. The device architecture was highly optimized to achieve a deep feature set in an uncomplicated in nature. The main architectural refinements leveraged the team’s broad exposure and experience in the desktop printer industry: a limited number of progressive die-stamped sheet metal parts forming the chassis, injection-molded plastic enclosures, multi-axis DC motor servo drive, and closed-loop position control. Strollo also developed a novel cutter actuation and force control mechanism that made a significant contribution to meeting the product cost goals.

Strollo is one of those rare organizations that melds people soft skills with technical hard skills to conjure up clever designs, no matter how difficult or mundane the project may be. Their professional approach and high integrity permeate all aspects of program scoping and execution. It is a pleasure to work with the Strollo team and I strongly recommend them to provide a solid solution to any technical challenge and deliver a great personal experience in the process.

Strollo worked diligently to develop enabling technologies and manufacturing processes as well as supporting numerous design activities. Mini was able to demonstrate the required set of functionalities with a limited number of prototype builds and was quickly transitioned to the contract manufacturer. Strollo worked in tandem with the Cricut team onsite in Asia to successfully bring up manufacturing tooling and the CM’s manufacturing line.