what strollo provided

As a repeat client, Cricut sought Strollo’s collaborative efforts and in-depth experience. Together we were able to develop an innovative design and produce an advanced product that is different from any heat press on the market. Cricut Autopress™ is used for heat transfer projects by implementing iron-on, Heat Transfer Vinyl, and Cricut’s Infusible Ink™ to permanently apply designs onto a variety of base materials (fabrics, leather, woods, etc.).

For over two years I had the opportunity to work with the Strollo team developing Cricut’s best in class professional grade Autopress. During that time the Strollo team seamlessly integrated with not only the Cricut team but also developed strong and effective working relationship with our Asian based contract manufacturers. The Strollo team consistently demonstrated an impressive ability to balance engineering and design excellence with strategic company goals and timeline. I would wholeheartedly recommend joining forces with this powerhouse team who have demonstrated the ability to develop amazing products from cradle to grave.

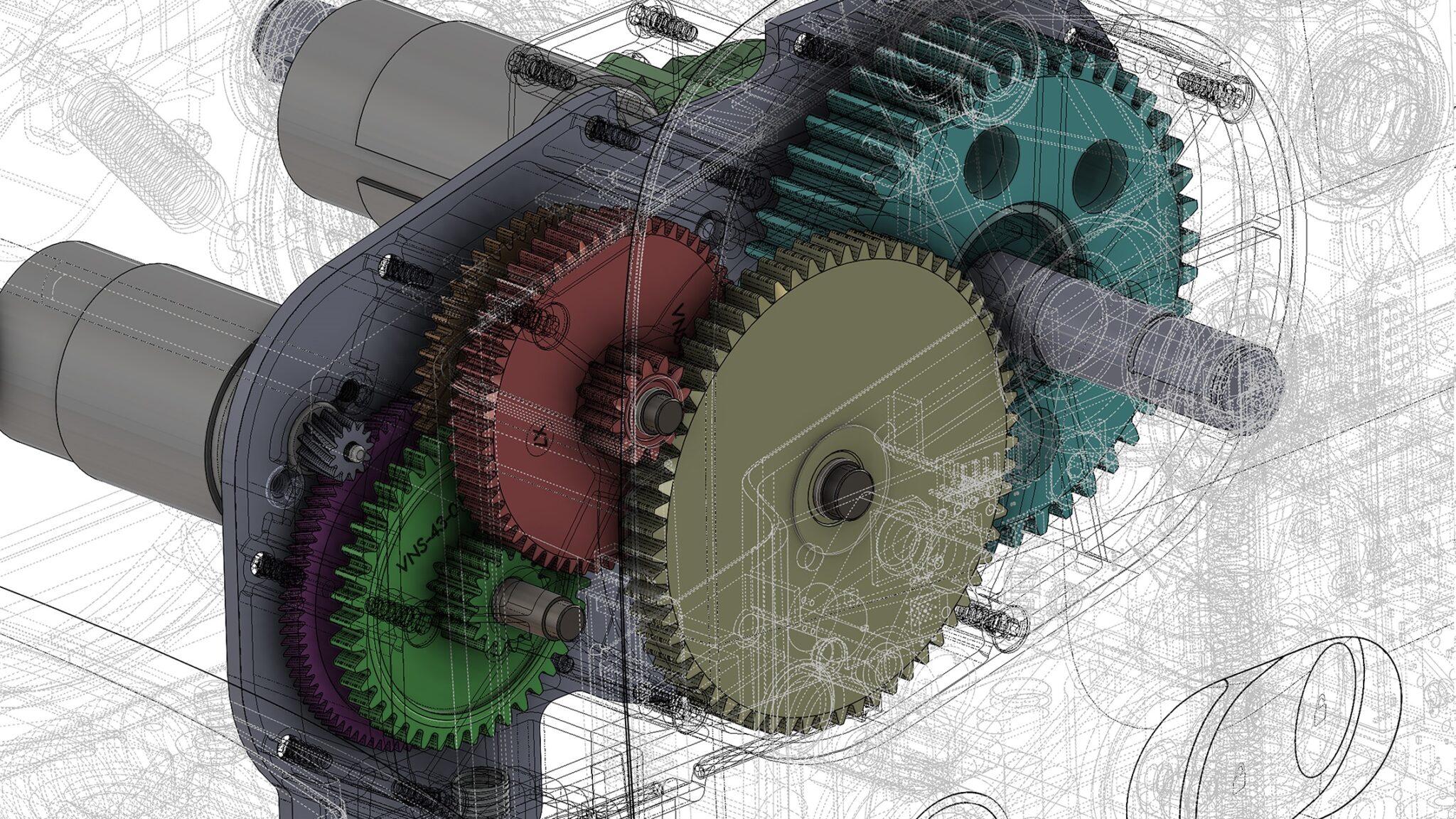

Strollo was introduced to the project during the ideation phase. As a trusted partner, we worked side by side with Cricut to refine the requirements, explore and analyze dozens of concepts, and then build a sequence of prototypes – all to ensure an optimal product architecture capable of achieving the aggressive program goals. The Strollo team brought to bear critical mechanical, electrical, compliance, and software engineering to develop innovative kinematic geometry, motion control systems, thermal management, and ultimately patent-pending IP to bring this product to realization. We integrated effectively with Cricut’s contract manufacturer in Asia, from concept through mass production, to provide onsite guidance and manufacturing development during critical pre-production prototype builds through to full manufacturing release.